In an era where branding and consumer experience define success, companies are turning to personalized tote bags OEM solutions to create functional products that also serve as long-term marketing tools. These custom tote bags do more than just carry items—they carry your brand story, sustainability values, and market positioning. This article Cohen Bag explores two critical aspects of the industry: the OEM customization process and technical excellence, and the brand marketing value that personalized tote bags OEM delivers.

The Complete OEM Customization Process Behind Personalized Tote Bags OEM

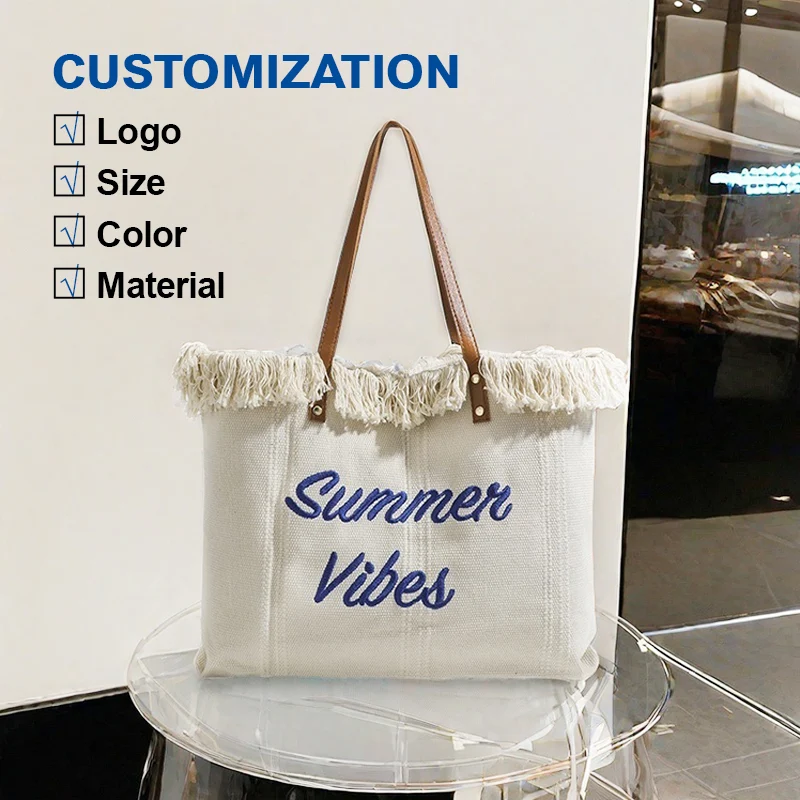

When a business decides to produce customized tote bags, working with an OEM manufacturer provides the advantage of professional-grade customization, consistent quality, and efficient mass production. Unlike generic suppliers, an OEM partner works closely with your brand from the design stage to the finished product.

Requirement Definition and Design Consultation

The first step in any personalized tote bags OEM project is clear communication of requirements. The client defines the purpose of the tote bags—whether for retail packaging, promotional giveaways, or premium merchandise.

During the consultation stage, the OEM team translates brand elements into technical specifications. This includes:

-

Bag size and dimensions (standard, shopper, mini, etc.)

-

Fabric type (cotton canvas, jute, non-woven PP, RPET, or polyester)

-

Handle length and stitching type

-

Logo positioning, Pantone colors, and finishing details

A professional OEM supplier provides technical drawings, mock-ups, and digital prototypes for pre-production review.

Material Selection and Testing

Material is the foundation of quality. A good personalized tote bags OEM supplier offers a full range of eco-friendly and durable materials that align with brand values.

Common options include:

-

Cotton Canvas: Classic and strong, ideal for fashion brands and daily use.

-

Organic Cotton: 100% biodegradable and certified sustainable.

-

Recycled PET Fabric (rPET): Made from recycled plastic bottles, promoting eco-conscious branding.

-

Jute and Linen: Natural fibers with a rustic, premium look.

-

Non-woven Polypropylene: Lightweight, cost-effective for mass events.

Each fabric undergoes tests for tear resistance, colorfastness, and print adhesion. Some manufacturers also provide GRS (Global Recycled Standard) and OEKO-TEX® certifications to ensure compliance with environmental standards.

Printing, Embellishment, and Branding Techniques

The design stage defines your tote bag's personality. OEM suppliers provide a variety of decoration methods that enhance brand identity and longevity.

-

Screen Printing: Ideal for simple, bold logos with excellent durability.

-

Digital Printing (DTG): Allows complex multi-color artwork without setup costs.

-

Heat Transfer: Perfect for detailed graphics or gradient color logos.

-

Embroidery: Adds texture and a premium, high-end aesthetic.

-

Sublimation: Long-lasting color embedding for polyester fabrics.

An experienced personalized tote bags OEM partner helps clients choose the best printing method based on fabric, color vibrancy, and intended use.

Sample Approval and Pre-Production

Before mass production, a prototype sample is created. This phase confirms every technical and visual detail—fabric color, stitching quality, logo clarity, and handle strength.

Adjustments are made until the sample perfectly matches brand standards.

This meticulous approach ensures that once full-scale production begins, every unit reflects the same level of precision and consistency.

Mass Production and Quality Control

High-volume production is where true OEM strength shines. Modern factories integrate automated cutting machines, color-matching systems, and computer-controlled sewing lines to ensure efficiency.

Each personalized tote bags OEM batch goes through multi-stage quality inspections:

-

Incoming Material Check – Verifying raw fabric and print quality.

-

In-process Inspection – Random checks during sewing and printing.

-

Final AQL Testing – Assessing product dimensions, strength, and packaging.

-

Compliance Review – Meeting REACH, CPSIA, or Prop 65 standards for international trade.

A reputable OEM manufacturer delivers detailed inspection reports, giving clients full transparency and trust in every shipment.

Packaging, Labeling, and Global Logistics

Tote bags aren't just shipped; they're presented. Packaging can include custom polybags, printed kraft boxes, or even biodegradable wrapping.

For global exporters, personalized tote bags OEM suppliers manage everything from SKU labeling and barcoding to container optimization and drop-shipping to e-commerce centers.

A thoughtful packaging design strengthens your brand story the moment the customer unboxes it.

The Branding and Marketing Power of Personalized Tote Bags OEM

Personalized tote bags are no longer simple giveaways—they are strategic marketing assets. When manufactured through OEM channels, they offer unmatched branding control, helping companies turn a practical product into a mobile advertising platform.

Enhancing Brand Visibility and Recognition

Every tote bag acts as a walking billboard. Whether used in supermarkets, offices, or travel, it continuously displays your logo and message.

With personalized tote bags OEM, you can define every branding element—from typography and slogan to color palette—so it perfectly aligns with your corporate identity.

Unlike short-lived promotional materials, tote bags deliver long-term brand exposure at minimal recurring cost.

Emotional Connection and Customer Loyalty

Consumers today value authenticity and personalization. When customers receive or purchase a personalized tote bags OEM product, they associate your brand with thoughtfulness and quality.

Imagine an eco-friendly skincare company giving customers organic cotton totes featuring minimalist design and sustainability messages. Every time that bag is reused, the brand's environmental values are reinforced.

Such emotional resonance drives repeat engagement, word-of-mouth marketing, and social media sharing—all contributing to organic visibility.

Versatile Applications Across Industries

OEM customization enables brands from diverse sectors to leverage tote bags effectively:

-

Retail & Fashion: Limited-edition merchandise or packaging that doubles as accessories.

-

Corporate Events: Branded giveaways that leave a professional impression.

-

Education & Conferences: Useful souvenirs that attendees actually reuse.

-

Hospitality & Travel: Complimentary totes for hotels, resorts, and travel kits.

-

Eco Campaigns: Promote sustainability initiatives through reusable alternatives to plastic.

Each application demonstrates how personalized tote bags OEM turns marketing expenditure into long-term brand investment.

Sustainability as a Marketing Advantage

Modern consumers favor brands that act responsibly. Partnering with an OEM supplier using recycled or organic materials, non-toxic dyes, and energy-efficient processes adds real substance to your sustainability claims.

By communicating these features on your tote bags and packaging, you show transparency and environmental responsibility—qualities that strengthen brand reputation and customer trust.

Case Insight: How Personalized Tote Bags OEM Drove ROI

A boutique fashion label collaborated with a personalized tote bags OEM partner to create 15,000 organic cotton totes featuring unique hand-drawn artwork and embroidered logos.

-

Distributed as free gifts for orders over $100.

-

Shared across social media with campaign hashtags.

-

Led to a 40% increase in online engagement and 25% sales growth within 3 months.

This example highlights how the right OEM collaboration transforms simple accessories into measurable marketing performance.

The Long-Term Value of OEM Partnership

Choosing a long-term OEM partner gives you not only production consistency but also creative flexibility. Once the initial design and mold are established, reorders are effortless, lead times shorten, and unit costs drop significantly.

A stable personalized tote bags OEM partnership ensures that your brand can regularly refresh seasonal designs, launch co-branded projects, or create limited runs—without compromising quality or timelines.

In today's competitive market, personalized tote bags OEM offers the perfect balance between technical excellence and brand strategy. Through a structured customization process—design consultation, material selection, precise printing, and rigorous quality control—brands can produce tote bags that are both functional and emotionally engaging. From eco-conscious consumers to corporate clients, these custom tote bags communicate quality, sustainability, and authenticity in every detail. Partnering with an experienced personalized tote bags OEM manufacturer ensures that every product becomes a meaningful extension of your brand identity—one that customers carry with pride, visibility, and trust.

https://www.conhenbag.com/how-personalized-tote-bags-oem-redefines-custom-manufacturing.html

https://www.conhenbag.com/Tote-Bag

www.conhenbag.com

Dongguan Cohen Bag Industry Co., Ltd.

+ There are no comments

Add yours