In the rapidly evolving field of robotics, choosing the right switching component is crucial for efficiency, reliability, and overall system performance. Two primary options dominate the market: MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) and traditional switching components, such as mechanical relays or bipolar junction transistors (BJTs). Understanding their differences can significantly impact your robotic system design.

1. Efficiency and Switching Speed

MOSFETs excel in high-speed switching applications, thanks to their low gate charge and fast response times. In robotics:

-

Faster actuation: Motors and sensors respond quicker to control signals.

-

Reduced power loss: Less heat generation during switching improves energy efficiency.

Traditional relays and BJTs, by contrast, have slower switching speeds and higher conduction losses, which can limit the responsiveness of precise robotic systems.

2. Thermal Management and Reliability

-

MOSFETs handle higher currents with lower voltage drops, reducing heat generation. This allows for smaller heat sinks and more compact robotic designs.

-

Traditional switching components often require larger thermal management systems to avoid overheating. In continuous operation scenarios, such as industrial robots or automated assembly lines, MOSFETs maintain performance more consistently over time.

3. Size and Integration

Modern robotics often demands compact and lightweight solutions. MOSFETs:

-

Offer high power density in small packages.

-

Support surface-mount and multi-pack configurations, simplifying PCB design and reducing space.

Traditional components are bulkier and can increase system weight, making them less suitable for mobile or precision robots.

4. Durability and Lifespan

MOSFETs provide longer operational lifespans due to the absence of moving parts and reduced mechanical wear. This is critical for:

-

Industrial robotic arms operating 24/7.

-

Autonomous mobile robots requiring reliable, low-maintenance components.

Traditional electromechanical relays, while robust in low-frequency switching, experience mechanical fatigue and contact degradation over time.

5. Versatility and Applications

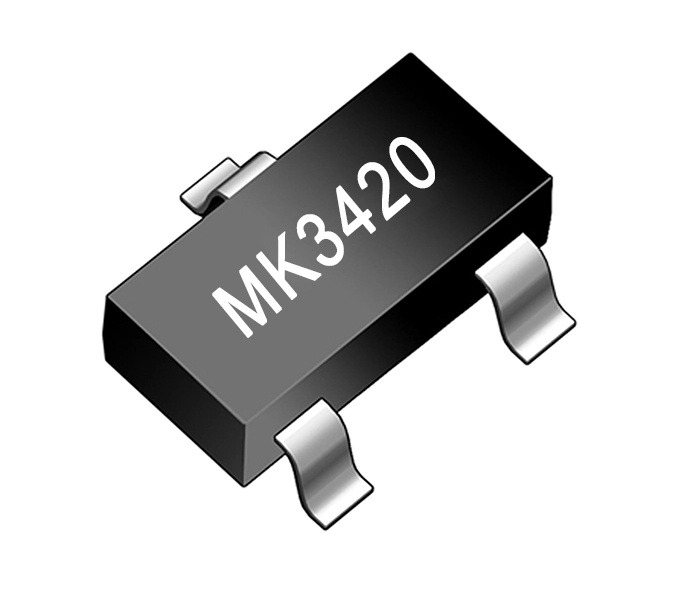

Mengke Electronics, a national high-tech enterprise, offers high-performance MOSFETs with diverse packaging and customization options. Their MOSFETs are widely applied in:

-

Industrial automation equipment: High-current motor control and precision actuators.

-

Home automation and robotics kits: Compact and energy-efficient switching.

-

Mobile and intelligent devices: Fast-response electronics requiring minimal heat loss.

By leveraging MOSFET technology, robotic systems achieve superior efficiency, reduced energy consumption, and longer lifespans compared to designs relying solely on traditional switching components.

Conclusion

For most modern robotics applications, MOSFETs outperform traditional switching components in speed, efficiency, thermal management, size, and durability. Companies like Mengke Electronics provide high-quality, customizable MOSFET solutions that empower engineers to design next-generation robots with enhanced performance, reliability, and energy efficiency.

www.jymskj.com

Shenzhen Mengke Electronic Technology CO. LTD

+ There are no comments

Add yours