Quartz crystals are one of the most essential timing components in today’s electronic systems. From satellite navigation to autonomous driving, cloud computing, medical devices, and smart homes, nearly every modern technology relies on stable and accurate frequency sources. Despite their small size, quartz crystals play a critical role in maintaining synchronization, communication integrity, and operational reliability across countless products and industries.

This article explores how quartz crystals work, why they remain the preferred timing component, common application scenarios, and what engineers must consider when selecting the right crystal for their designs. It also highlights the capabilities of LUCKI ELECTRONIC (LUCKI®), a leading global manufacturer of quartz crystals, oscillators, ceramic resonators, and timing components.

To explore quartz crystal products, you can visit:

<a href="https://www.cnlucki.com/Quartz-Crystal">Quartz Crystal Solutions</a>

1. Why Quartz Crystals Matter in Electronics

Every electronic system that processes signals, communicates, or coordinates events requires precise timing. Quartz crystals serve as the heartbeat of these systems by providing a stable oscillation frequency.

Key Advantages of Quartz Crystals

-

High frequency stability across temperature changes

-

Low aging rate, ensuring long-term accuracy

-

Excellent Q factor, supporting low phase noise

-

Cost-effective manufacturing for high-volume applications

-

Compact footprint, suitable for miniaturized devices

As industries demand faster data rates, more accurate positioning, and more complex real-time processing, quartz crystals remain foundational to achieving system-level performance.

2. How Quartz Crystals Generate Stable Frequency

Quartz possesses a natural piezoelectric property. When voltage is applied, the crystal resonates at a specific frequency determined by its cut and geometry.

Factors Impacting Frequency Performance

-

Crystal cut type (AT, BT, SC, etc.)

-

Mechanical stress from assembly

-

Temperature cycling

-

Drive level and load capacitance

-

Aging rate and internal contamination

Because of these sensitivities, manufacturing precision is critical. LUCKI ELECTRONIC (LUCKI®) has refined production processes over decades to ensure consistency, reliability, and international-level precision across its quartz crystal product lines.

3. Types of Quartz Crystals and Their Applications

Quartz crystals come in multiple configurations, each optimized for a specific set of requirements.

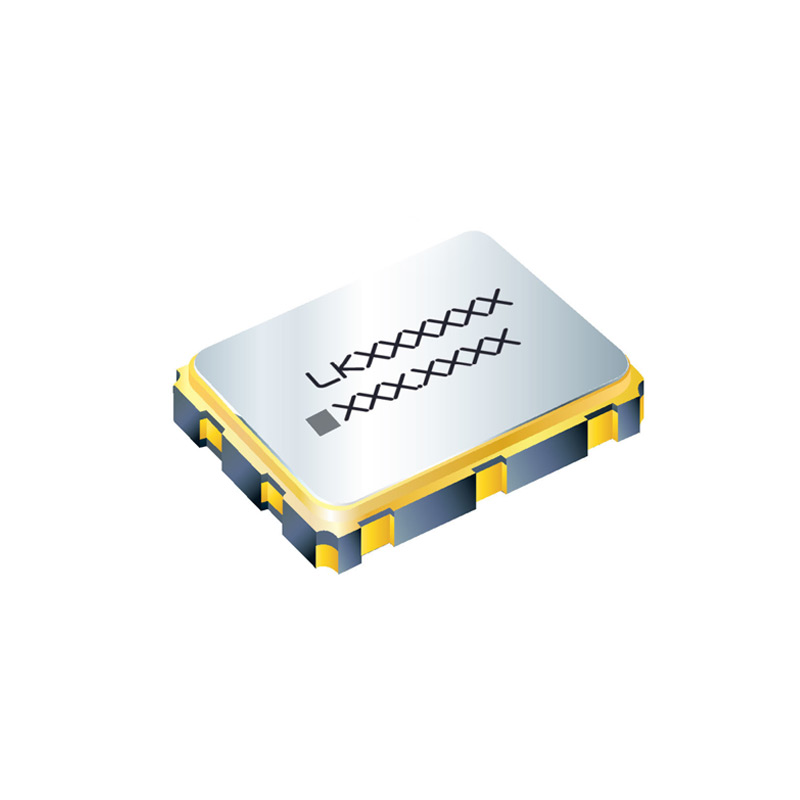

SMD Quartz Crystals

Used widely in:

-

Mobile devices

-

Smart home controllers

-

IoT endpoints

-

Consumer electronics

Compact size and automated PCB assembly compatibility make SMD crystals ideal for large-scale manufacturing.

Through-Hole Quartz Crystals

Still preferred in applications needing:

-

High mechanical stability

-

Easier manual replacement and testing

-

Longer lead lengths for thermal isolation

Often used in industrial machines and legacy systems.

Temperature-Compensated Crystals (TCXO)

Used in:

-

GNSS systems

-

Cellular base stations

-

High-speed communication modules

TCXOs provide excellent stability across wide temperature ranges.

Voltage-Controlled Crystals (VCXO)

Ideal for systems requiring frequency tuning, such as:

-

Network synchronization

-

Jitter-cleaning circuits

-

PLL-based timing systems

Oven-Controlled Crystals (OCXO)

Provide ultra-high stability for:

-

Scientific instruments

-

Aviation and satellite communication

-

Precision measurement systems

-

HPC and data center timing

LUCKI® offers full product lines across TCXO, VCXO, OCXO, and SMD/through-hole crystals—each designed to meet rigorous industrial and communication standards.

4. Key Applications Powered by Quartz Crystals

Quartz crystals play a central role in a wide range of modern technologies.

A. Satellite Navigation (GNSS)

GNSS receivers require precise timing to calculate distance via signal travel time. A slight timing drift can cause significant positioning errors.

LUCKI® provides crystals and TCXOs with low aging and temperature stability ideal for high-precision navigation.

B. 5G/6G Base Stations

Base stations rely on synchronized timing to manage channel allocation, beamforming, and data transmission.

Quartz crystals enable stable communication with minimal jitter and phase noise.

C. Data Servers and Cloud Platforms

Timing errors can cause data corruption or packet loss.

Crystals provide clock signals for processors, network cards, storage controllers, and security modules.

D. Artificial Intelligence and Autonomous Driving

AI accelerators and vehicle sensors depend on synchronized sampling and real-time data fusion.

Quartz timing ensures algorithms operate reliably under dynamic conditions.

E. Smart Homes and IoT Devices

Low-power quartz crystals maintain consistent performance in environments where chip-level timing is critical for wireless connectivity and long battery life.

F. Industrial Control and Automation

Industrial equipment requires stable timing signals for motor control, measurement, and safety systems.

Crystals withstand vibration and temperature variations common in industrial environments.

G. Medical Devices

From imaging to patient monitoring, medical equipment demands reliability and accuracy.

Quartz crystals offer the stability required for sensitive medical applications.

With customers in over 50 countries and more than 10 billion timing components delivered globally, LUCKI ELECTRONIC supports virtually every major electronics sector.

5. Common Failure Modes and How to Avoid Them

Quartz crystals are reliable, but certain conditions can lead to performance degradation.

A. Frequency Drift (Aging)

Caused by internal contamination or material stress.

Solution: Select crystals with low aging rates and ensure proper PCB assembly.

B. Temperature Instability

Outdoor or industrial environments can cause frequency variation.

Solution: Use TCXO or OCXO for temperature-sensitive applications.

C. EMI and Crosstalk

Nearby high-frequency circuits can introduce noise.

Solution: Proper PCB layout with isolation and grounding.

D. Mechanical Shock and Vibration

Industrial and automotive vibration can stress crystals.

Solution: Choose devices with mechanical reinforcement or appropriate mounting strategies.

E. Incorrect Load Capacitance

Mismatch between crystal and oscillator circuit affects frequency accuracy.

Solution: Validate circuit design and manufacturer recommendations.

LUCKI®’s engineering teams provide support to ensure that crystal selection and design integration meet application-specific requirements.

6. Selecting the Right Quartz Crystal for Your Application

Choosing a quartz crystal involves evaluating multiple parameters beyond nominal frequency.

Key Selection Criteria

-

Frequency stability (ppm over temperature)

-

Load capacitance

-

Package size (SMD or through-hole)

-

Drive level

-

Equivalent series resistance (ESR)

-

Aging characteristics

-

Environmental tolerance (shock, vibration, humidity)

Because timing requirements vary significantly among satellite navigation, consumer electronics, industrial equipment, and AI servers, LUCKI ELECTRONIC offers tailored crystal options and engineering guidance to match performance and environmental needs.

7. Future Trends: Why Quartz Crystals Remain Essential

Even with emerging timing technologies such as MEMS oscillators, quartz crystals continue to dominate high-reliability applications due to:

-

Superior long-term stability

-

Lower phase noise

-

Better aging characteristics

-

Wider frequency range

-

Compatibility with demanding RF and high-speed applications

As AI, autonomous driving, renewable energy systems, and smart city infrastructure expand, the demand for precise timing only increases.

LUCKI® continues to invest in R&D for next-generation quartz crystal and oscillator technologies to support evolving global requirements.

Conclusion

Quartz crystals remain one of the most reliable and widely used timing components in modern electronics. Their stability, low cost, and versatile application range make them indispensable across industries from satellite navigation to AI and industrial automation.

With decades of experience, complete SMD and through-hole product lines, and global delivery exceeding 10 billion timing solutions, LUCKI ELECTRONIC (LUCKI®) continues to lead the frequency component industry. Their quartz crystal products support reliable performance in communication, computing, smart technology, healthcare, energy systems, and beyond.

Choosing the right quartz crystal—and integrating it properly—ensures stable timing performance, long-term reliability, and higher system efficiency in today’s sophisticated electronics landscape.

www.cnlucki.com

LUCKI ELECTRONIC(LUCKI®)

+ There are no comments

Add yours