As the global population grows and the demand for food increases, agricultural practices must evolve to ensure higher productivity and environmental sustainability. Among the many tools driving this transformation, the fertilizer granulator machine has emerged as a cornerstone in modern agriculture. By converting raw fertilizer materials into efficient, user-friendly granules, these machines have revolutionized fertilizer production and application. In this article, Little Sky explores the critical functions of fertilizer granulator machines, providing insights into why they are vital to today’s farming industry.

What is a Fertilizer Granulator Machine?

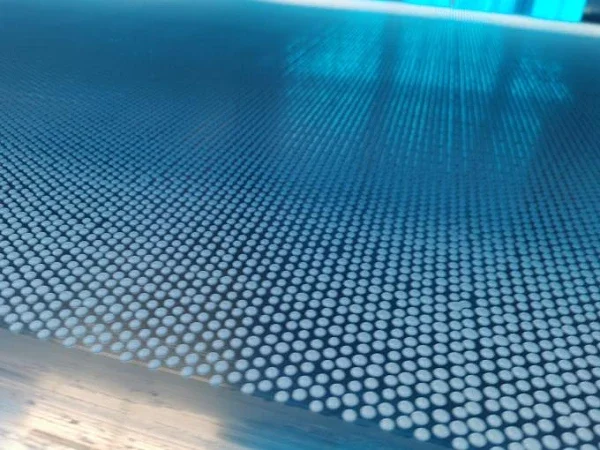

A fertilizer granulator machine is specialized equipment used to create uniform granules from powdered or raw fertilizer materials. These granules enhance the physical and chemical properties of fertilizers, making them more efficient for agricultural use. Unlike traditional forms of fertilizers, granular fertilizers are easier to apply, store, and transport. The machine employs various technologies to compact or agglomerate raw materials into solid granules of desired shapes and sizes.

Fertilizer granulator machines are integral to the production of both organic and inorganic (chemical) fertilizers, helping manufacturers achieve consistency in quality and performance. These machines come in various types, each designed for specific materials and production requirements.

How Fertilizer Granulator Machines Promote Sustainability

1. Recycling Organic Waste

Fertilizer granulator machines play a pivotal role in addressing the challenges of organic waste management. These machines transform agricultural residues, animal manure, food waste, and other biodegradable materials into high-value fertilizer granules. Without this recycling process, organic waste often ends up in landfills or is incinerated, contributing to greenhouse gas emissions and environmental pollution. By reintroducing these materials into the agricultural cycle, granulator machines promote a circular economy where waste is no longer discarded but repurposed to enrich the soil. This approach not only reduces the carbon footprint of farming operations but also helps farmers access a cost-effective and sustainable source of nutrients.

2. Reducing Chemical Dependency

Over-reliance on synthetic chemical fertilizers has long been a concern due to their detrimental effects on soil health and ecosystems. Fertilizer granulator machines address this issue by enabling the production of organic fertilizers and biofertilizers. Organic fertilizers derived from natural waste materials enhance soil organic matter and improve microbial diversity, fostering healthier and more resilient soils. Similarly, biofertilizers introduce beneficial microorganisms that assist in nutrient cycling and nitrogen fixation. By reducing the need for chemical inputs, farmers can prevent soil acidification, safeguard biodiversity, and reduce water contamination caused by nutrient runoff. This transition to organic and biofertilizers aligns with global efforts to promote sustainable agriculture practices.

3. Improving Fertilizer Efficiency

Traditional fertilizers, particularly in powder or liquid forms, are prone to losses through leaching into groundwater or volatilization into the atmosphere. Granulated fertilizers produced by fertilizer granulator machines offer a solution by delivering nutrients in a compact and stable form. These granules dissolve gradually, ensuring a controlled and consistent release of nutrients that match crop demands over time. This precision reduces waste and maximizes plants' nutrient uptake, leading to improved crop yields. Additionally, the durability and uniform size of granules facilitates easier application using modern machinery, reducing labor costs and ensuring even nutrient distribution across fields.

4. Supporting Eco-Friendly Farming

Eco-friendly farming practices prioritize reducing the environmental footprint of agricultural operations, and fertilizer granulator machines align perfectly with these goals. The controlled release of nutrients from granulated fertilizers minimizes the risk of nutrient runoff, which often causes algal blooms and dead zones in water bodies. This protection of aquatic ecosystems is critical for maintaining biodiversity and water quality. Furthermore, granulator machines enable the production of slow-release fertilizers that provide long-term soil benefits, reducing the frequency of fertilizer application and conserving resources. By integrating these technologies, farmers can adopt a more sustainable approach to soil fertility management, ensuring both environmental preservation and long-term agricultural productivity.

The fertilizer granulator machine has become a cornerstone of modern agriculture, offering unparalleled benefits in terms of efficiency, customization, and sustainability. By transforming raw materials into high-quality granules, these machines empower farmers and manufacturers to meet the growing demand for food while protecting the environment. Whether you are focused on organic farming, precision agriculture, or large-scale commercial operations, fertilizer granulator machines provide a versatile and reliable solution for maximizing productivity and sustainability in agriculture.

https://www.th-littlesky.com/Compound-Fertilizer-Granulator

www.th-littlesky.com

Little Sky Mechanical Engineering Kabushiki Kaisha

+ There are no comments

Add yours