In today's industrial landscape, efficient manufacturing processes are at the heart of production success. Whether it's in the food, pharmaceutical, or personal care industries, the need for high-quality products that meet stringent standards is ever-growing. One essential ingredient in many of these industries is CMC (Carboxymethyl Cellulose), a versatile and highly functional polymer used in a wide variety of applications, including as a thickening agent, binder, and stabilizer. To produce this valuable material, an efficient CMC production line is crucial. A CMC production line is specifically designed for the manufacturing of carboxymethyl cellulose, ensuring that the process is optimized for maximum output, consistency, and quality.

What is a CMC Production Line?

A CMC production line is a fully integrated system of machines and processes designed for the efficient and consistent production of carboxymethyl cellulose (CMC). CMC is a water-soluble polymer derived from natural cellulose, and it is prized across industries for its ability to modify viscosity, stabilize emulsions, form gels, and improve texture. By streamlining the production process, a CMC production line ensures that manufacturers achieve reliable output with the desired purity, viscosity range, and particle size distribution.

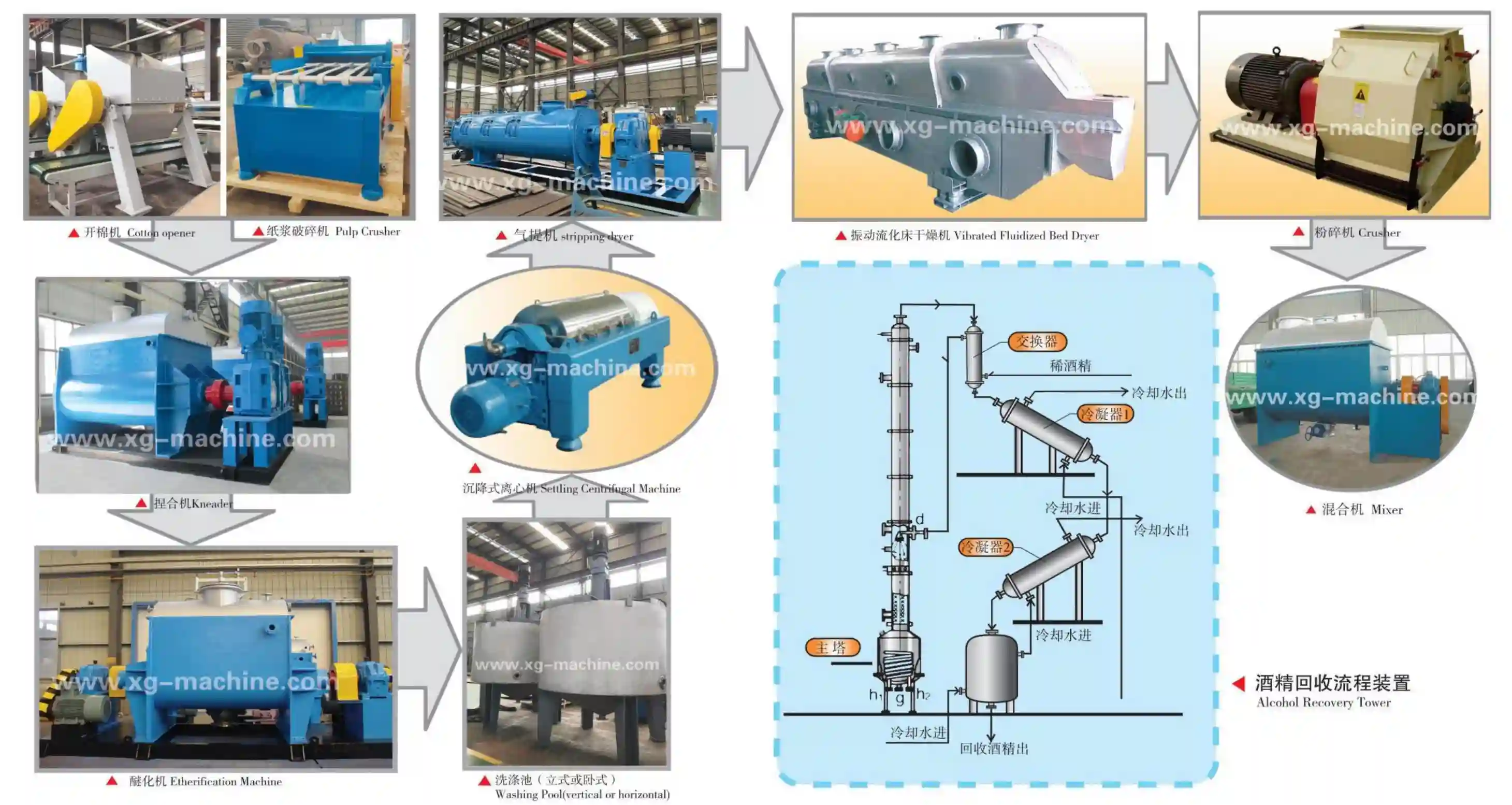

The CMC production line typically includes several interconnected stages that work in harmony to transform raw cellulose into a versatile polymer:

-

Pre-treatment of Cellulose: Cellulose fibers undergo mechanical and chemical preparation, making them suitable for the carboxymethylation process. This step directly influences the reactivity and quality of the final CMC.

-

Carboxymethylation Reaction: The cellulose reacts with chloroacetic acid and sodium hydroxide under controlled conditions, creating the carboxymethyl cellulose structure. This stage is the heart of the CMC production line and determines the degree of substitution (DS), which defines the product's performance characteristics.

-

Purification: After the reaction, impurities and by-products must be removed. Advanced purification systems within the production line ensure high purity levels, which are essential for food, pharmaceutical, and cosmetic applications.

-

Drying and Milling: The purified CMC is dried and then milled to achieve the required particle size and form. This final step ensures the CMC is ready for packaging and downstream applications.

By automating and optimizing each stage, the CMC production line guarantees consistency, cost efficiency, and adherence to strict industry standards.

How a CMC Production Line Impacts Different Industries

A CMC production line is not just an asset for chemical producers—it is the backbone of multiple industries that depend on high-quality CMC for their products. The ability of the production line to ensure uniformity and precision directly affects the performance and reliability of products in pharmaceuticals, food, cosmetics, and oil drilling. Below is a closer look at how these sectors benefit.

1. Pharmaceutical Industry

In the pharmaceutical industry, precision and consistency are critical. Carboxymethyl cellulose is widely used as a binder, thickener, and stabilizer in formulations such as tablets, capsules, and liquid suspensions. A CMC production line ensures that the polymer is produced with the highest standards of purity and uniform viscosity, both of which are essential for drug safety and effectiveness.

For example, in tablet production, CMC helps maintain structural integrity while also ensuring proper disintegration and dissolution once ingested. If the viscosity or purity fluctuates, the efficacy of the drug can be compromised. With a well-optimized CMC production line, pharmaceutical manufacturers can produce CMC that consistently meets pharmacopeia requirements, reducing risks and ensuring patient safety.

2. Food Industry

The food industry heavily depends on the consistency of ingredients, and CMC is no exception. Acting as a stabilizer, thickener, and emulsifier, CMC helps improve texture, mouthfeel, and shelf life in products like sauces, ice cream, baked goods, and dairy alternatives.

A high-quality CMC production line guarantees that food-grade CMC is produced with uniform viscosity and particle size. This is essential because even slight variations can affect product appearance, stability, and taste. For example, in ice cream, CMC prevents ice crystal formation, leading to a smoother texture. In salad dressings, it ensures uniform thickness and prevents ingredient separation. The precision of the CMC production line gives food manufacturers confidence that their products will meet consumer expectations every time.

3. Personal Care and Cosmetics

In cosmetics and personal care, product texture and user experience are paramount. CMC is widely incorporated into lotions, creams, shampoos, and gels as a thickening and stabilizing agent. It enhances the viscosity of formulations, improves spreadability, and contributes to a luxurious feel.

A CMC production line enables cosmetic manufacturers to produce CMC with consistent quality, ensuring that the polymer integrates seamlessly into formulations. By controlling the degree of substitution and particle size, the production line provides tailored CMC suitable for different product types. For instance, in a body lotion, the CMC must deliver a smooth, rich texture without leaving a sticky residue. In shampoos, it must stabilize the formula while contributing to the right flow properties. The reliability of the CMC production line is what makes these formulations perform consistently on a large scale.

4. Oil and Gas Industry

The oil and gas industry places unique demands on materials, and CMC is a key ingredient in drilling fluids. As a viscosifier, it controls fluid rheology, ensuring proper suspension of drill cuttings, stabilization of the borehole, and smooth drilling operations.

The CMC production line ensures that CMC intended for oilfield applications is produced with the right viscosity profile and thermal stability. This is vital because drilling conditions are extreme, with high temperatures, pressures, and varying chemical environments. CMC from a well-designed production line can withstand these conditions without losing its performance characteristics. The result is enhanced drilling efficiency, reduced operational risks, and better overall wellbore stability.

A CMC production line is much more than a set of machines—it is a carefully engineered system that transforms raw cellulose into a versatile polymer with countless industrial applications. Its precision and efficiency directly impact industries as diverse as pharmaceuticals, food, cosmetics, and oil and gas. By guaranteeing purity, viscosity control, and consistent particle size, the CMC production line ensures that every end-use application achieves its desired outcome—whether it's a stable drug formulation, a creamy ice cream, a smooth lotion, or a high-performing drilling fluid. For manufacturers, investing in a robust CMC production line is not only about efficiency; it's about delivering quality, safety, and performance in every product.

https://www.globalkneader.com/optimizing-manufacturing-efficiency-with-a-cmc-production-line.html

https://www.globalkneader.com/CMC-production-line

www.globalkneader.com

Nantong Kneading Mixing Machine Co., Ltd

+ There are no comments

Add yours