In the world of industrial machinery, precision and efficiency are paramount. One of the essential components that keep machines running smoothly are ball bearings, specifically deep groove ball bearings. These bearings are used in a variety of applications ranging from automotive engines to high-speed machinery, providing low friction, durability, and reliability. In this blog post, CONSUMMATE will share the role of deep groove ball bearing assembly machine in manufacturing and its features.

What is Deep Groove Ball Bearing?

Before delving into the workings of an assembly machine, it' s important to understand what deep groove ball bearings are and why they are crucial to so many industries. A deep groove ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. These bearings are designed to support both radial and axial loads, making them highly versatile. They are widely used in everything from electric motors and household appliances to industrial machinery and automotive parts.

The deep groove design allows the bearing to accommodate both radial and axial forces, making it ideal for high-speed and high-load applications. The simple design, combined with its effectiveness, makes it one of the most commonly used bearings in the world.

Role of Deep Groove Ball Bearing Assembly Machine

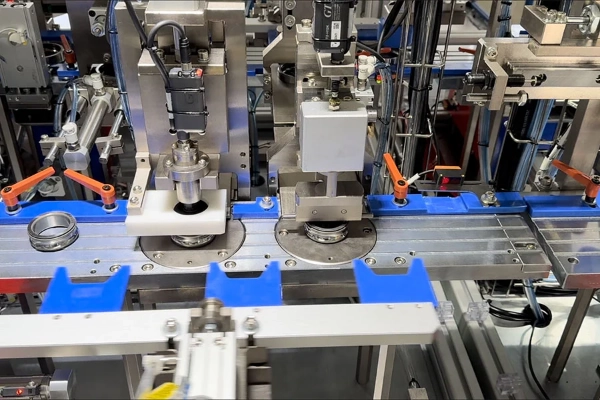

A deep groove ball bearing assembly machine is designed specifically for assembling these ball bearings with speed and precision. It automates the often-complex process of placing balls into the raceways, securing the inner and outer rings, and ensuring that the final product meets the stringent quality standards required in today' s manufacturing environment.

The process of assembling deep groove ball bearings manually is time-consuming and prone to human error. Components must be perfectly aligned, the correct number of balls must be inserted, and the bearing must be closed without causing damage. The slightest deviation can lead to increased wear, noise, and ultimately, failure of the bearing. This is where the deep groove ball bearing assembly machine comes into play, improving the efficiency and reliability of the process.

Features of Deep Groove Ball Bearing Assembly Machine

1. High Precision: One of the most significant benefits of the assembly machine is its ability to assemble bearings with high precision. The machine uses advanced robotic arms and sensors to ensure that every ball is placed correctly and that the inner and outer races are properly aligned. This level of precision ensures that the bearings can handle high loads and high speeds without failure.

2. Automation: The assembly machine drastically reduces the need for manual labor. Traditional methods of assembling ball bearings required skilled workers to perform repetitive and intricate tasks. The deep groove ball bearing assembly machine automates this process, reducing labor costs and the potential for human error.

3. Speed and Efficiency: Assembly time is drastically reduced with the use of the machine. Where it would take several minutes for a skilled worker to assemble a bearing manually, the assembly machine can complete the task in just a few seconds. This significant reduction in assembly time leads to higher production rates and the ability to meet high demand without sacrificing quality.

4. Consistency: Consistency is crucial in bearing manufacturing. Even slight variations in the size or alignment of the components can compromise the performance of the bearing. The deep groove ball bearing assembly machine ensures that every bearing is assembled with the same level of precision, leading to more reliable and uniform products.

5. Cost-Effectiveness: Though the initial investment in a deep groove ball bearing assembly machine can be significant, the long-term savings it offers make it a worthwhile investment. With reduced labor costs, higher production efficiency, and less material wastage, manufacturers can achieve higher profit margins and lower the cost per unit of production.

How Deep Groove Ball Bearing Assembly Machine Works?

1. Component Loading: The machine receives the individual components of the bearing, including the inner race, outer race, and balls, which are often stored in a hopper or on a conveyor belt. The parts are fed into the machine in a controlled manner, ensuring the correct orientation and alignment for each component.

2. Ball Insertion: One of the most crucial steps in the process is inserting the balls into the bearing. The machine uses specialized feeders to pick up the balls and position them into the raceways of the inner and outer rings. This step must be performed with utmost precision to ensure that the balls are evenly spaced and properly seated.

3. Ring Assembly: After the balls are placed in the raceways, the machine positions the inner and outer races together. Depending on the design, the assembly machine may either press the races together or use a centrifugal force to ensure they lock into place. The precise alignment of the races is critical to ensure smooth operation and long-lasting performance.

4. Sealing: For certain applications, the ball bearing may require seals or shields to prevent contaminants from entering the bearing or to retain lubricants. The assembly machine can also be equipped to insert these seals automatically, ensuring that the bearing is fully enclosed and ready for use.

5. Quality Control: After the bearing is assembled, the machine often performs a series of checks to ensure that the finished product meets quality standards. These can include visual inspections, ultrasonic testing, or automated measurements to check for any defects or misalignments.

6. Packaging: Once the bearings are assembled and inspected, the machine may also have an integrated packaging system that places the finished bearings into protective packaging for shipment.

Benefits to Manufacturers

1.Reduced production time: Automation speeds up the assembly process and allows manufacturers to produce bearings more quickly, meeting tighter deadlines and larger order volumes.

2.Improved product quality: With the increased precision of automated assembly, the quality of the bearings is more consistent, reducing defects and returns.

3.Lower labor costs: The need for manual labor is greatly reduced, saving costs on workforce management while also ensuring fewer errors in the production process.

Conclusion

The deep groove ball bearing assembly machine has become a game-changer in bearing production, offering increased speed, precision, and cost-effectiveness. For manufacturers, adopting this advanced technology means the ability to scale production, reduce human error, and maintain high-quality standards. As industries continue to demand more efficient and reliable components, the deep groove ball bearing assembly machine stands as a testament to the power of automation in modern manufacturing.

https://www.jscst.vip/Role-of-Deep-Groove-Ball-Bearing-Assembly-Machine-in-Manufacturing.html

www.jscst.vip

CONSUMMATE

+ There are no comments

Add yours