In the world of automotive engineering, fuel pumps play a vital role in ensuring the smooth and efficient operation of internal combustion engines. These devices are responsible for delivering the correct amount of fuel to the engine at the right pressure and flow rate. But have you ever wondered how fuel pumps are controlled? In this article, we will delve into the intricate control mechanism behind fuel pumps, exploring the various technologies and systems involved.

- Mechanical Fuel Pump Control:

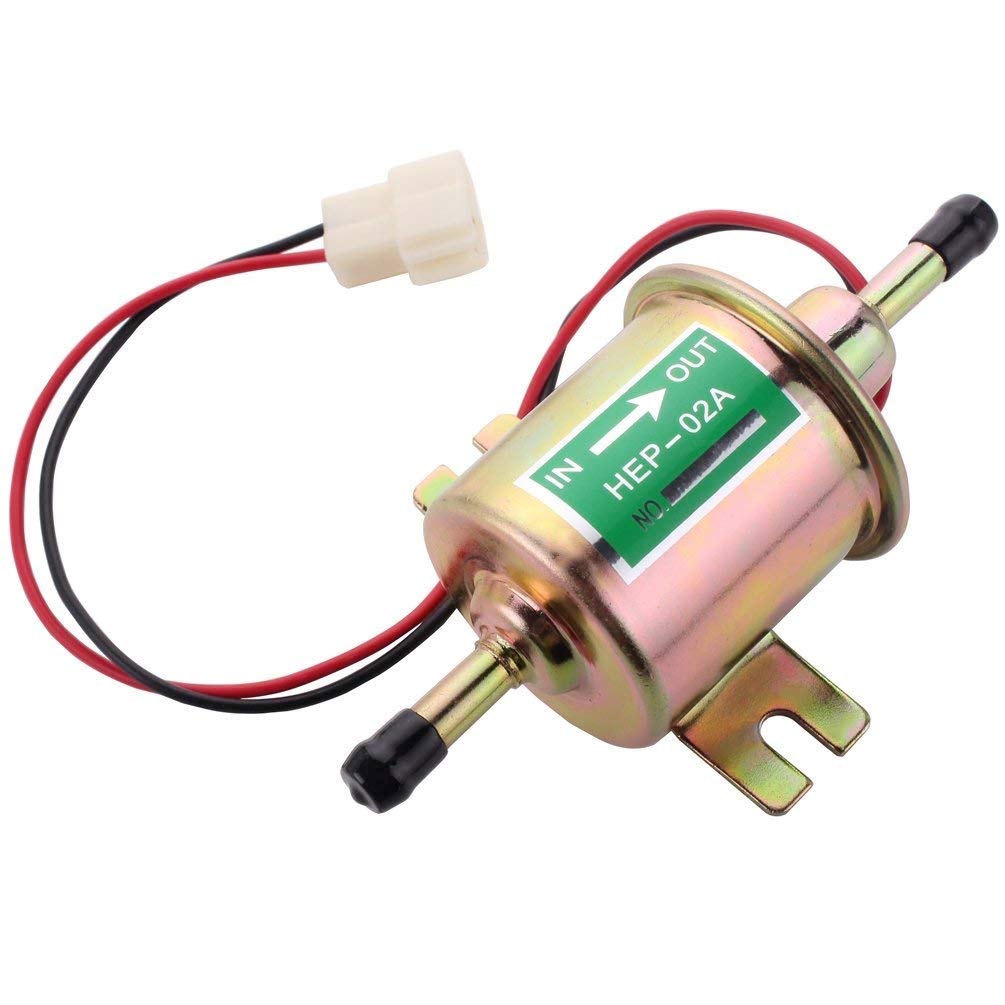

Traditionally, fuel pumps were mechanically controlled by a camshaft or eccentric mechanism. As the engine rotated, the camshaft or eccentric would actuate a lever, which in turn operated the fuel pump diaphragm. This mechanical linkage ensured that the fuel pump delivered fuel in synchronization with the engine's requirements. However, with the advent of electronic fuel injection systems, mechanical control mechanisms have become less common. - Electronic Fuel Pump Control:

Modern vehicles predominantly employ electronic fuel injection systems, which necessitate electronic control of the fuel pump. The engine control unit (ECU) plays a crucial role in this process. By continuously monitoring various engine parameters such as engine speed, load, and temperature, the ECU can precisely regulate the fuel pump's operation. - Fuel Pressure Regulation:

One of the primary functions of fuel pump control is to maintain the optimal fuel pressure within the system. The ECU receives input from various sensors, including the fuel pressure sensor, and adjusts the fuel pump's speed or duty cycle accordingly. By modulating the pump's operation, the ECU ensures that the fuel pressure remains within the desired range, guaranteeing efficient combustion and engine performance. - Variable Speed Fuel Pumps:

To further enhance fuel efficiency and adaptability, some modern vehicles employ variable speed fuel pumps. These pumps can adjust their rotational speed based on the engine's demand, allowing for precise control of fuel delivery. By operating at lower speeds during low-load conditions, variable speed fuel pumps reduce energy consumption and minimize unnecessary fuel flow. - Fuel Pump Driver Modules:

In many vehicles, fuel pump control is facilitated by dedicated modules known as fuel pump driver modules (FPDMs). These modules serve as intermediaries between the ECU and the fuel pump, translating the control signals into appropriate voltage or current levels. FPDMs also incorporate safety features such as overcurrent protection and diagnostic capabilities, ensuring reliable and secure fuel pump operation.

Conclusion:

The control mechanism behind fuel pumps is a complex and sophisticated system that has evolved significantly over the years. From mechanical linkages to electronic control units, the automotive industry has embraced advanced technologies to optimize fuel delivery and engine performance. Understanding how fuel pumps are controlled is crucial for automotive engineers and enthusiasts alike, as it enables us to appreciate the intricacies of modern engine management systems and their impact on overall vehicle efficiency.

+ There are no comments

Add yours