As robotics and automation continue to reshape the manufacturing and engineering landscapes, the demand for high-precision, high-performance mechanical components has never been greater. One such critical component at the heart of many modern motion systems is the planetary reducer.

Known for their compact size, efficiency, and high torque transmission, planetary reducers are essential to achieving accurate and controlled motion—especially in robotic arms, automated guided vehicles (AGVs), CNC machinery, and more. This article explores their core functions and highlights how Yijiaang, a professional transmission component company, empowers industries with precision-engineered planetary gear solutions.

What Is a Planetary Reducer?

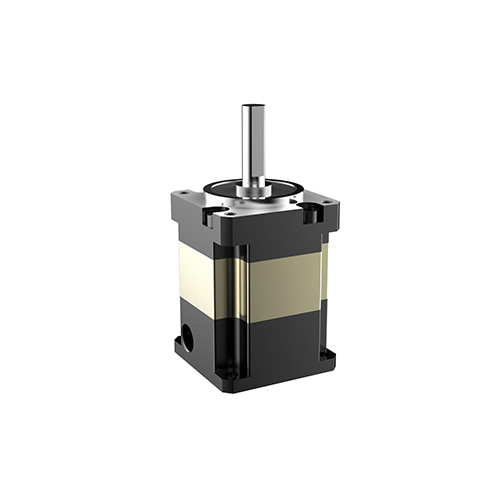

A planetary reducer, also known as a planetary gearbox, is a type of gear reducer that uses a central sun gear, multiple planet gears, and an outer ring gear. The planet gears rotate around the sun gear and are held in place by a carrier, enabling torque distribution across multiple contact points.

This configuration allows planetary reducers to:

Transmit high torque in a compact form factor

Offer high efficiency and smooth operation

Maintain precise control at high reduction ratios

Key Functions of Planetary Reducers in Robotics and Automation

1. Speed Reduction and Torque Multiplication

One of the primary functions of planetary reducers is to reduce motor speed while increasing output torque. In robotic applications, this is crucial for:

Lifting or moving heavy payloads with small servo motors

Achieving fine motion control at low speeds

Preventing motor overloading during high-load tasks

Yijiaang’s planetary reducers are designed to provide optimized gear ratios and torque multiplication while maintaining stability and responsiveness, even in dynamic or demanding industrial environments.

2. High Precision and Positioning Accuracy

Modern robotics requires millimeter-level precision, particularly in tasks like pick-and-place, assembly, or surgical robotics. Planetary gear systems excel in minimizing backlash—unwanted play between gears—ensuring accurate, repeatable movements.

Yijiaang employs advanced manufacturing techniques and high-grade materials to achieve ultra-low backlash, making their reducers ideal for:

Collaborative robots (cobots)

6-axis industrial arms

CNC and 3D printing applications

3. Compact Design for Space-Constrained Systems

Space is often limited in robotic systems. The coaxial design of planetary gearboxes allows for a high power-to-size ratio, making them ideal for installations where every millimeter counts.

Yijiaang’s engineering team works closely with clients to offer custom solutions, ensuring that the gearbox fits seamlessly into the design of robotic joints, rotary tables, or automated machinery, without sacrificing performance.

4. High Efficiency and Smooth Transmission

Planetary gear systems offer excellent efficiency—often above 95%—due to the even load distribution among planet gears and minimal energy loss. This contributes to:

Lower energy consumption

Reduced heat generation

Extended service life of the system

Yijiaang’s reducers are precisely machined and heat-treated to ensure smooth meshing and long-term durability, even under continuous duty cycles.

5. Robustness and Load Capacity

The multiple gear contacts within a planetary system allow it to handle higher loads compared to other gear types of similar size. This makes them perfect for:

Heavy-duty automation

Servo-driven systems

Robotics operating in challenging environments

Yijiaang’s planetary gearboxes are built to industrial-grade standards, with options for shock resistance, corrosion protection, and IP-rated sealing for dusty or humid settings.

Yijiaang: Driving the Future of Intelligent Motion

With years of expertise in the development and application of mechanical transmission components, Yijiaang has become a trusted partner in the fields of robotics, automation, and precision machinery. Here's what sets them apart:

✅ Tailored Engineering Support

Yijiaang offers customized gearbox solutions for specific application needs, from torque specs to mounting configurations and motor interface compatibility.

✅ Technical Service & Integration

From product selection to installation guidance and after-sales support, Yijiaang provides full-cycle technical services, ensuring optimal integration into your system.

✅ Diverse Product Portfolio

In addition to planetary reducers, Yijiaang offers a wide range of transmission components including couplings, gear racks, and servo drive accessories—supporting complete motion solution ecosystems.

Applications Across Industries

Planetary reducers supplied by Yijiaang serve a wide array of industries:

Industrial Robotics: For joint actuation and precise motion control

Medical Automation: In surgical robots or diagnostic equipment

Packaging and Logistics: In AGVs, conveyors, and palletizing machines

Precision Machinery: CNC tools, laser cutters, and more

Final Thoughts

As intelligent automation continues to advance, planetary reducers will remain a foundational component in ensuring precision, reliability, and performance in motion systems. Whether in a robotic welding arm or an automated storage solution, their role is both essential and irreplaceable.

Yijiaang, with its deep industry experience and customer-first philosophy, is paving the way for smarter, more efficient mechanical systems. For businesses seeking trusted partners in motion transmission, Yijiaang delivers not just components—but complete, reliable solutions.

Navigating the World of Planetary Reducers: A Guide to Selection and Usage

www.yijiaangreducers.com

Suzhou Yijiaang Automation Technology Co., Ltd.

+ There are no comments

Add yours