In the realm of materials science, PLA (Polylactic Acid) has emerged as a fascinating contender, captivating the attention of researchers, engineers, and manufacturers alike. This biodegradable thermoplastic polymer has gained popularity due to its unique combination of properties, making it a strong contender in various industries. In this article, we delve into the strength of PLA, exploring its versatility and applications across different domains.

- Understanding the Strength of PLA:

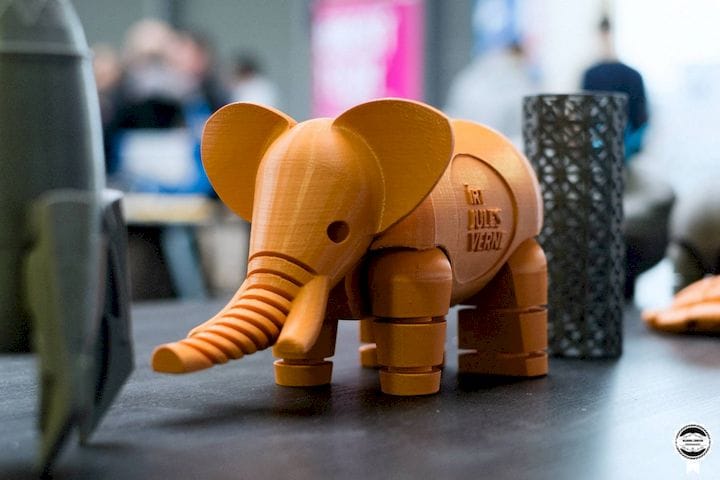

PLA possesses several notable strengths that contribute to its widespread adoption. Firstly, its mechanical properties, such as tensile strength and impact resistance, make it a formidable material for various applications. PLA's tensile strength rivals that of traditional petroleum-based plastics, allowing it to withstand considerable loads without deformation or failure. Additionally, its impact resistance ensures durability, making it suitable for applications that require robustness. - Versatility in Manufacturing:

PLA's strength extends beyond its mechanical properties. Its versatility in manufacturing processes is a key factor contributing to its popularity. PLA can be easily molded, extruded, and 3D printed, enabling the creation of complex shapes and intricate designs. This adaptability makes PLA an ideal choice for industries such as automotive, aerospace, and consumer goods, where customization and design intricacy are paramount. - Sustainable Advantages:

One of PLA's greatest strengths lies in its eco-friendly nature. Derived from renewable resources such as cornstarch or sugarcane, PLA offers a sustainable alternative to conventional plastics derived from fossil fuels. Its biodegradability ensures minimal environmental impact, as it can break down into harmless components under specific conditions. This characteristic makes PLA an attractive choice for industries seeking to reduce their carbon footprint and embrace sustainable practices. - Applications Across Industries:

PLA's strength and versatility have led to its adoption in various industries. In the packaging industry, PLA-based films and containers provide a lightweight and durable alternative to traditional plastics. In the medical field, PLA finds applications in surgical implants, drug delivery systems, and tissue engineering due to its biocompatibility and biodegradability. Moreover, PLA's use in 3D printing has revolutionized the manufacturing landscape, enabling the production of prototypes, consumer products, and even architectural models. - Future Prospects and Innovations:

As research and development in PLA continue to advance, new innovations and applications are on the horizon. Researchers are exploring methods to enhance PLA's mechanical properties further, making it a viable substitute for certain metals and engineering plastics. Additionally, efforts are underway to improve PLA's heat resistance, expanding its potential in high-temperature applications.

Conclusion:

In conclusion, PLA stands as a strong material with a multitude of strengths that contribute to its growing popularity. Its mechanical properties, versatility in manufacturing, sustainable advantages, and diverse applications across industries make it a compelling choice for various purposes. As the world embraces sustainability and seeks alternatives to traditional plastics, PLA's strength and potential continue to shine, paving the way for a greener and more innovative future.

+ There are no comments

Add yours