In laboratory and semiconductor industries, maintaining a contamination-free environment is critical for both product quality and personnel safety. A Class 100 clean bench—also known as a laminar flow bench—provides a controlled workspace that minimizes particulate and microbial contamination. Companies like Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd., a leading developer and manufacturer of laboratory and semiconductor plastic equipment, design and produce high-quality clean benches that meet stringent contamination control requirements.

What Is a Class 100 Clean Bench?

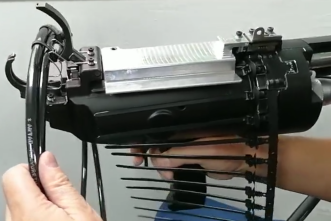

A Class 100 clean bench is an enclosed workspace designed to maintain air cleanliness at a level of 100 particles per cubic foot of air (0.5 μm or larger), as defined by ISO Class 5 standards. The bench achieves this by filtering air through high-efficiency particulate air (HEPA) filters and delivering a unidirectional, laminar airflow across the work surface. This consistent airflow prevents airborne contaminants from entering the work area, protecting sensitive samples, components, and processes from contamination.

Key Features of Class 100 Clean Benches

-

HEPA Filtration System

The core of a Class 100 clean bench is its HEPA filter, which captures 99.97% of airborne particles 0.3 microns and larger. Xinruiwei Semiconductor Technology integrates European-grade components into their clean benches, ensuring reliable filtration and long-term performance. -

Laminar Airflow Design

Laminar flow ensures that filtered air moves in parallel streams over the work surface, sweeping away any potential contaminants. This minimizes turbulence and prevents cross-contamination, making the workspace ideal for sensitive semiconductor components, microbiology experiments, or pharmaceutical applications. -

Durable and Ergonomic Construction

Clean benches must be durable and easy to maintain. Xinruiwei clean benches feature high-quality plastic and stainless steel construction, providing a chemically resistant, smooth surface that is easy to clean and disinfect. Ergonomic designs also ensure user comfort during long hours of work. -

Reliable Airflow and Contamination Control

The bench is engineered to maintain consistent airflow and filtration efficiency, even under continuous operation. This reliability is critical for laboratories and semiconductor facilities where precision and cleanliness directly affect product quality and experimental outcomes.

Benefits of Using a Class 100 Clean Bench

1. Protects Sensitive Materials

Class 100 clean benches prevent airborne dust, microbes, and other contaminants from contacting sensitive materials. This is essential in semiconductor manufacturing, cell culture, or laboratory testing, where even minor contamination can compromise results or damage products.

2. Improves Product Quality and Consistency

By providing a contamination-free workspace, clean benches help maintain product integrity and consistency. Laboratories can achieve more accurate experimental results, while semiconductor manufacturers ensure defect-free production processes.

3. Enhances Laboratory Safety

A controlled airflow environment reduces the risk of accidental exposure to potentially hazardous substances. In addition, clean benches prevent the spread of contaminants to other areas, protecting staff and maintaining overall laboratory hygiene.

4. Increases Operational Efficiency

A well-designed clean bench streamlines workflow by providing a ready-to-use, controlled environment. With Xinruiwei’s customizable solutions, laboratories can scale from prototypes to batch production while maintaining consistent cleanliness and productivity.

Xinruiwei Semiconductor Technology: Trusted Clean Bench Solutions

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. specializes in the development and manufacturing of laboratory and industrial plastic equipment for semiconductor and laboratory applications. Using European components and strict quality control, Xinruiwei delivers clean benches and other laboratory devices that meet the highest standards for performance and reliability. Their customizable solutions—from prototypes to full-scale production—allow laboratories and manufacturing facilities to maintain contamination-free environments efficiently and safely.

Conclusion

A Class 100 clean bench is an indispensable tool for laboratories and semiconductor industries that require a contamination-free workspace. By combining HEPA filtration, laminar airflow, and ergonomic design, these benches protect sensitive materials, improve product quality, enhance safety, and streamline operations. With advanced clean bench solutions from Xinruiwei Semiconductor Technology, laboratories and manufacturing facilities can ensure consistent, reliable contamination control and maintain the highest standards of performance and precision.

www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.

+ There are no comments

Add yours